Royal Brompton Hospital

Project stats

Project Overview

JP Dunn Construction were appointed by Kier to complete the groundworks and concrete frame works for a new 3,417m² imaging centre at Royal Brompton Hospital in London. Royal Brompton & Harefield is the largest specialist heart and lung healthcare provider in the UK. Its new imaging centre will provide diagnostic facilities for patients and enable several innovative treatments, including interventional bronchoscopy.

The imaging centre includes two storeys below ground for plant, services, and MRI scanners, and two storeys above ground. The ground and first floors include echocardiography, transoesophageal echocardiogram, CT scanners, and clinical support accommodation.

Key Features

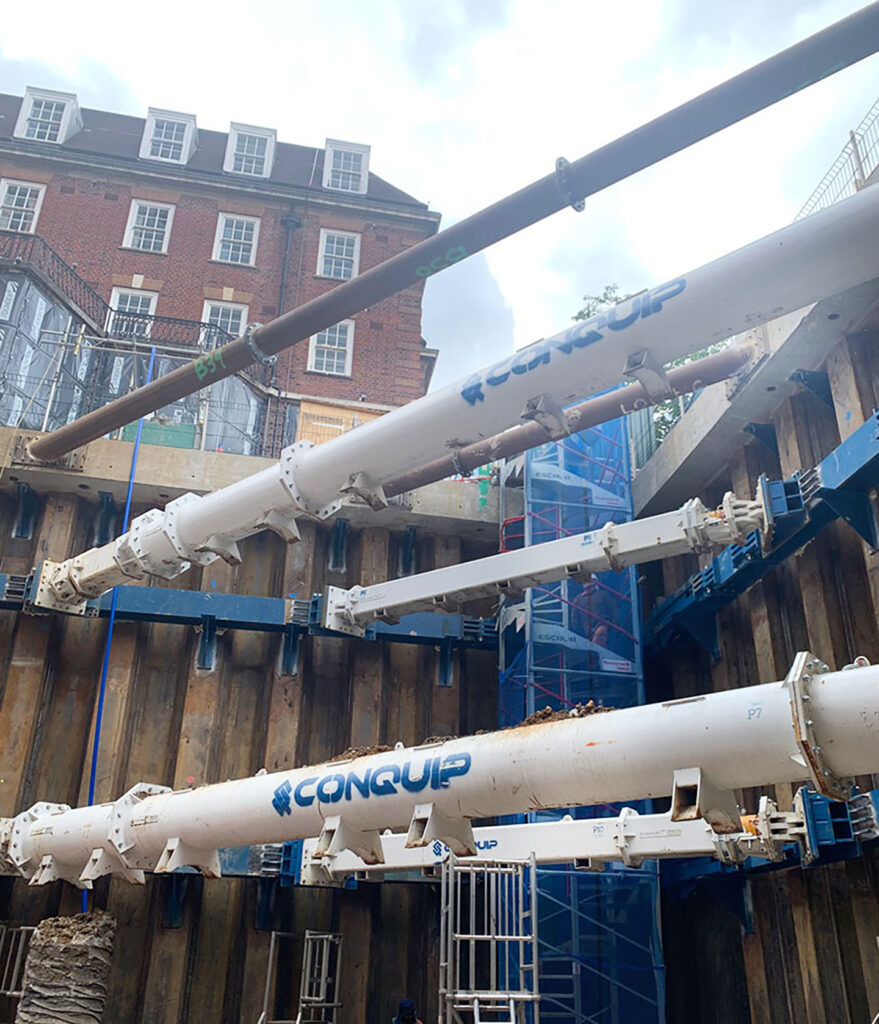

A substantial part of the building is subterranean, so JP Dunn’s temporary works design expertise supported the piled walls, tower crane, and a loading gantry supported on plunge columns. The 9m deep basement was constructed using sheet piled walls propped at three levels with hydraulic and fixed steel props. A temporary loading gantry was erected on plunge columns to allow muck-away vehicles to be loaded with the telescopic clamshell excavator. The tower crane was installed early, supported on plunge columns before excavation began.

JP Dunn collaborated closely with FIS to develop the waterproofing design as a CDP element. A combination of waterproof concrete and cavity drain system was installed to achieve a Grade 3 watertight basement to BS 8102:2009 standards.

A telescopic clamshell excavator was deployed to efficiently remove spoil from the excavation area, enabling works to be carried out at a depth of 9 metres. This specialised equipment was selected for its ability to reach deep excavation levels while maintaining precision and control in confined spaces. Its use ensured safe and effective spoil extraction, minimising disruption to surrounding areas and supporting the overall progress of the project.

Instead of being disposed of in a landfill, the gravel spoil generated during the project was responsibly transported to a licensed recycling facility. This approach supported the project’s commitment to sustainable waste management by enabling the material to be processed and reused, thereby reducing environmental impact and conserving natural resources.